FLAT TYPE WIRE WOUND RTD

These types of RTDs are used in measuring the temperature of the winding of the Motor and Generator. They are placed in the slot available in the stator-winding core.

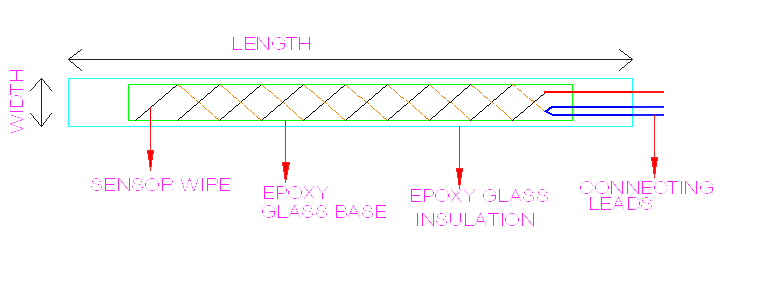

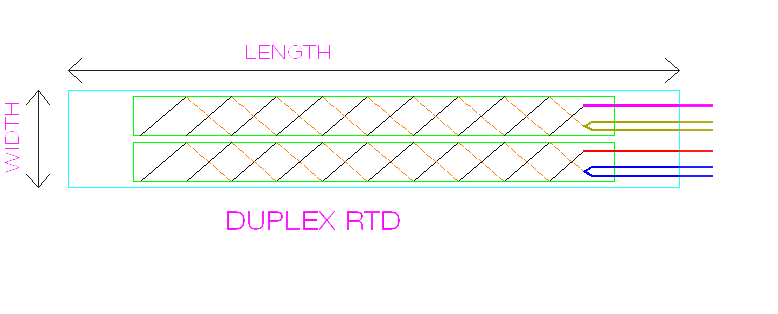

These Flat Type RTDs are made up of sensor wire (Platinum, Copper or Nickel) non-inductively wound on an epoxy glass base and are insulated with glass epoxy lamination. We are manufacturing these RTDs in Simplex (with single element) as well as Duplex (two sensors embedded in a single insulation) type.

These Long length Wire wound RTD is much better than thin film chip type RTD because the sensing elements of Wire wound RTD extend through most of the body length to provide an average temperature reading. This eliminates the danger of a point-type sensor missing a localized hot spot.

Our RTDs are moulded using hot curing epoxy resin.Technical Specifications: Our RTD’s has following Technical specification:-

1. Measure’s the temperature of Stator Winding of Electric motor from range –up to -50°C to +200°C.

2. Resistance wire is non-inductively wound.

3. Have H class insulation.

4. Accuracy:- For Platinum RTD:- R0 (Resistance at 0 Degree) tolerance ±0.06 Ω (class A), 0.12 Ω (Class B) & 0.25 Ω (Class C).

For Copper RTD:- R0 tolerance ±0.2%

For Nickel RTD:- R0 tolerance ±0.2% (class A) & ±0.5% (class B).

5. Dimensions as per costumer requirement. We have facility to manufacture RTD with thickness from 1MM to 10MM, width from 4MM to 40MM & Length from 25MM to 4000MM.

6. Insulation resistance between element and covering is greater than 100MΩ at room temprature & 20MΩ at 200°C .

7. Dielectric Strength:- Can withstand HV test at 2 Kv to 25 Kv. (increase in the thickness will increase the insulation strength of RTD).

8. The Leads wire specification will be as per costumer requirement. Generally we use 7x0.2MM & 19x0.15MM with PTFE/ETFE/FEP insulation. Leads color will be as per costumer requirement.

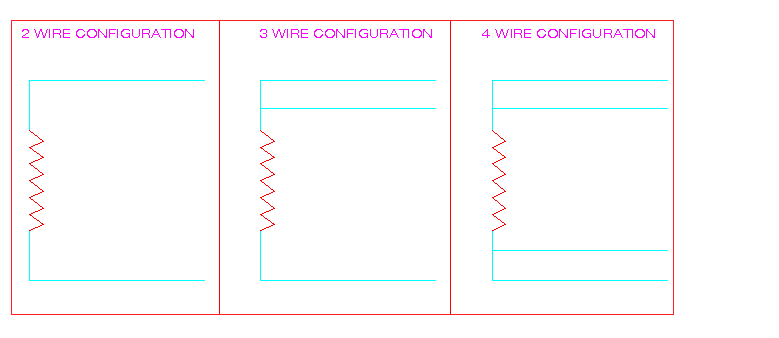

9. Lead wire combination will be 2wire/ 3wire/ 4wire as per costumer requirement.

10. The leads/joint will pass the pullout test of 3 Kg (for 7x0.2mm lead) & 5 KG (for 19x0.15 M). Minimum thickness of RTD for pullout test will be 2mm.

11. Our RTD will pass all tests mentioned in IEC60751, Clause 6. Our RTD will pass Stability at upper temperature limit, Thermoelectric effect, Self heating, insulation resistance at elevated temperatures, Thermal response time, Effect of temperature cycling, Hysteresis, Minimum immersion depth, Capacitance, Inductance, Vibration & Drop Test.

12. Any additional specific technical requirement will also be fulfilled.

13. RTDs will be supplied with Tests & calibration certificate.

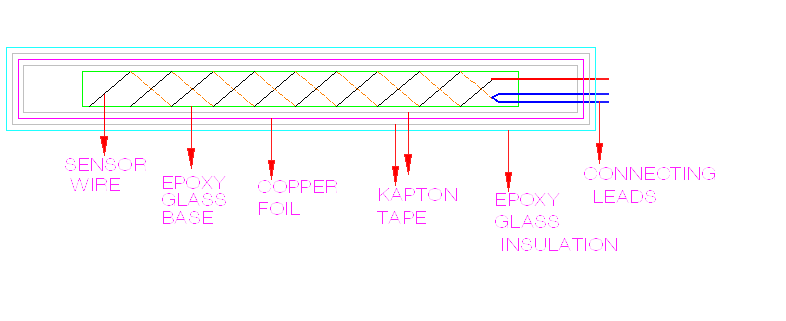

We are also manufacturing special type of winding RTD in which copper shielding is provided over the complete length of sensor.

Connecting Wire configuration of RTDs:-.

Connecting Wire configuration of RTDs:-.

Bearing RTD

These types of RTDs are also known as BTD (Bearing Temperature Detector) as they are generally used in measuring the temperature of bearing of Motor, Generator or turbine.

We are manufacturing wide range of BTDs as per costumers requirement. From Miniature RTD with dia of 2MM & Length of 20MM upto RTD with dia of 20MM & length 500MM are our routine product.

Some costumers are using RTD with insulated casings while some are using mineral insulated casings without any insulation.

RTD with Heads for turbo generators & Industrial furnaces

These types of RTDs are used in measuring the temperature of Air/ Gas/ Seal oil drain in turbo generators as well as in Industrial furnaces & ovens.

RTD with Mineral Insulated cables

These type of RTDs are used in Hydro Generators, and they are supplied with oil tight Gland Nut.

These RTD can work up to Temperature range of 200 degree C.

We manufacture these RTDs in simplex type (with single element) as well as duplex type (with two elements). These RTDs are supplied with mineral insulated cable. The conductor wire is insulated with MGO (Magnesium Oxide Powder) and placed inside a flexible copper sheath. Due to outer copper insulation it can be placed in an oily atmosphere. Sensor portion is placed inside SS or any other metallic casing as per costumer requirement.

Along with these above-mentioned RTDs we are also manufacturing some special type of RTDs as per costumer’s specifications.

.jpg)